Ejection Materials: |

|

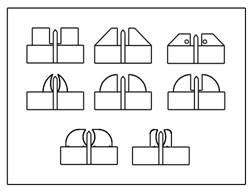

Sponge Rubber:

25° and 35° shore of different thicknesses, Available in Sheets, Normal strips, and Trapezium strips which prevent the sponge rubber from being pressed against the knife. |

|

Cell Polyurethane:

Ideal for the slot places which require harder rubber, Different thicknesses available in sheets, normal strips, and wave strips for corrugated boards.

|

|

Cork Rubber:

65° shore available in sheets and strips of different thicknesses. |

|

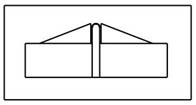

Cushion Crease:

Designed to reduce fractured scores caused by diecutting dry or recycled boards by gently crushing the inner liner. Available in rolls with different thicknesses. |

|

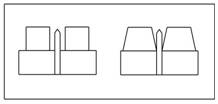

Profile Rubber:

The profile guides the material towards the knife. In this way the nicks are supported. Cutting-dust and board fragmentation are reduced.

|

|

EPDM Rubber:

The EPDM rubber prevents cracks in the surface of the material. Available in sheets and strips of different thicknesses. |

|

Stripping Foam:

Consists of two-layer ejection material made out of a soft and flexible body and a harder lower part. Reduces the amount of foam needed by approx. 70 %. Remains stable during the ejection process. Avoids cracks in the material. |

|